BaerCoil® Spark Plug Thread Repair Instructions for Use

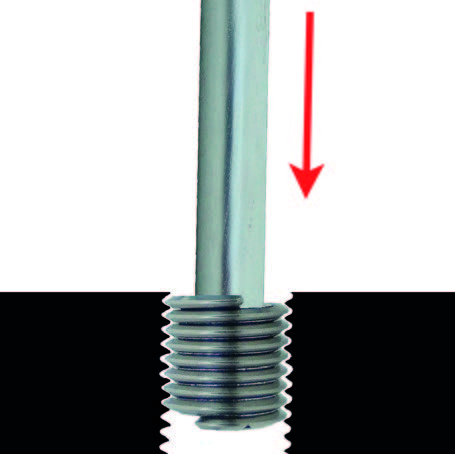

1. Drilling and tapping

For spark plug threads, no reaming is required, here use the combined drilling and cutting tool. The hole is expanded through the nose. Then the thread is cut with oversize. All in one pass.

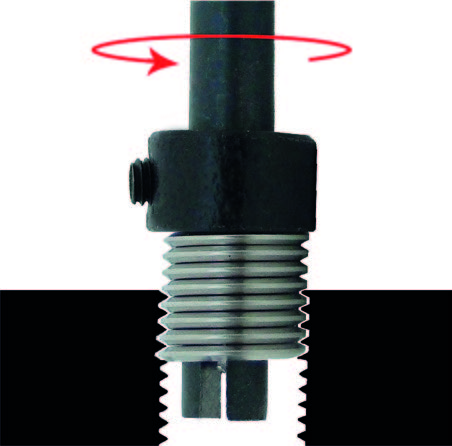

2. Install thread insert

Place the thread insert on the tool. Then fix the set collar so that the tang of the threaded insert sits in the center of the groove. Then, under light pressure, screw the threaded insert into the receiving thread until it is seated 1/4 - 1/2 turns below the surface.

DO NOT turn against the direction of travel, as the tang may break off.

3. Tang break

For spark plug threads, remove the tang with needle nose pliers.

Possible length adjustment

BaerCoil thread inserts can be shortened, according to the required length, with a side cutter or similar.

After completion of these operations, the tight and exact tolerances, as well as the forming

of the spring thread, have resulted in a thread that is often better and stronger than the original thread.

Application:

- Thread reinforcement of materials with low shear strength, e.g. aluminum & plastic, in mechanical engineering, automotive, electrical, medical and aerospace industries

- Thread repair of damaged and worn threads

- Scrap recovery